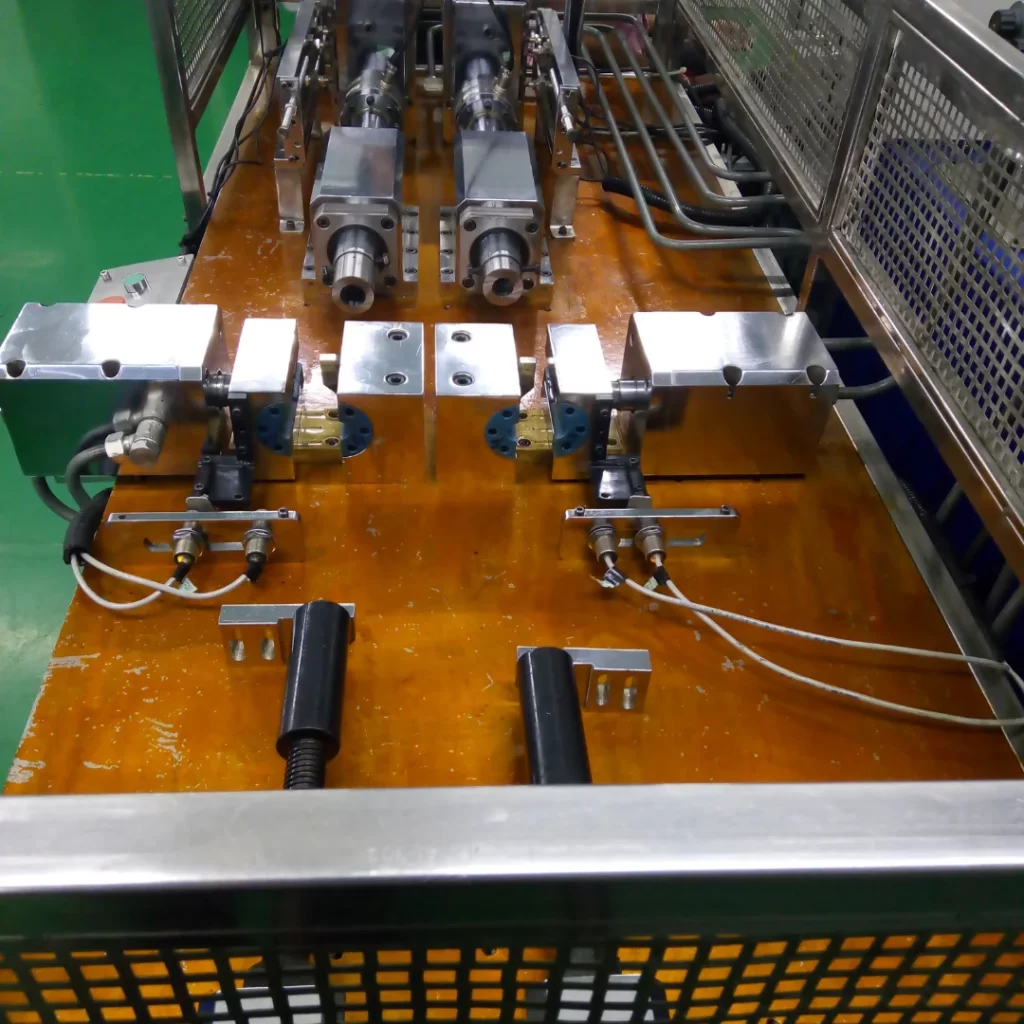

A pipe flaring machine is a mechanical tool used to create a flare on the end of a pipe. This process is typically used to improve the mechanical strength and leak-proof seal of a piping system by spreading the end of the pipe out into a bell shape. The flared end can then be attached to another flared end or to a fitting. Pipe flaring machines come in various types, including manual and hydraulic, and can be used on different materials such as copper, aluminum, and steel.

| Machine overall size | 1081×1551×581 |

| Operating Height | 950 mm from ground level |

| Job loading & unloading | Manually by operator |

| Power supply | 1Ǿ &230V & 50Hz AC Supply |

| Supply Air Pressure | 0.5MPa or 5bar |

Features:-

- Capacity: Pipe flaring machines are available in different capacities depending on the size of the pipe to be flared.

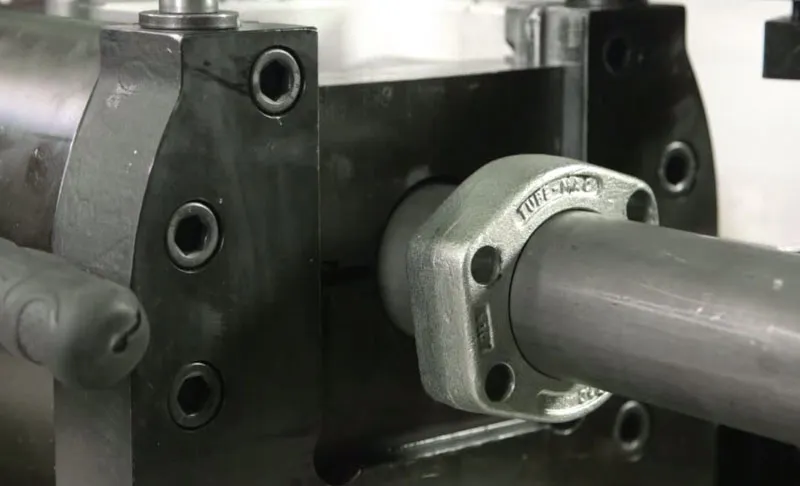

- Durability: A pipe flaring machine should be durable and made of high-quality materials to withstand the force and pressure required to flare the end of a pipe.

- Ease of use: The machine should be easy to operate, with clear instructions and controls that are easy to understand.

- Accuracy: The machine should be designed to provide accurate and consistent flaring results for every pipe flared.

- Versatility: Some pipe flaring machines are designed to flare different types of pipes, including copper, aluminum, and steel.

- Safety features: A pipe flaring machine should have safety features to prevent accidents and automatic shut-off features.

- Portability: Some pipe flaring machines are designed to be portable, making it easy to move the machine.

- Compatibility: The machine should be compatible with different types of fittings and pipes to ensure that the flared end fits snugly and securely.

- Maintenance: A pipe flaring machine should be easy to maintain and repair, with readily available replacement parts and a clear user manual.

- Cost: The cost of the machine should be reasonable and within the budget of the user.

Frequently Asked Questions :

Flaring a tube or pipe creates a wider end, which is essential for secure connections with fittings or other pipes

Yes, these machines are compatible with a variety of materials, ensuring versatility in applications

Pipe Flaring Machines create highly precise flares, ensuring a secure and leak-free connection.

Yes, they are designed for ease of use and can be operated with minimal training.

Maintenance requirements depend on usage, but regular upkeep ensures optimal performance.

Yes, many models offer adjustable settings for creating custom flares as needed.